RFID intelligent warehouse management

The demand for intelligent warehouse management is urgent at present, and RFID technology, which has many characteristics such as high security, long-distance recognition, accurate recognition, high durability, and reusability, has become a major tool for intelligent warehouse management. RFID technology is essential for achieving intelligent inventory counting. The automation and informatization of data collection in various operational processes such as warehouse arrival inspection, warehousing, outbound, transfer, relocation, and inventory counting have improved the accuracy and efficiency of warehouse management, making it more intelligent and simplified for enterprises to manage warehouse goods.

RFID intelligent warehousing

In RFID and industrial IoT based warehouse management solutions, any individual inventory item to be tracked will be equipped with RFID electronic tags. Each tag has a unique identification (ID) that contains encoded numerical data about inventory items, such as model, batch number, etc. The tag is scanned by an RFID reader, and after scanning, the reader extracts the tag's ID and transmits it to the cloud for processing.

The RFID (Radio Frequency Identification) system mainly consists of three parts: RFID electronic tags, RFID antennas (inlay), and RFID readers.

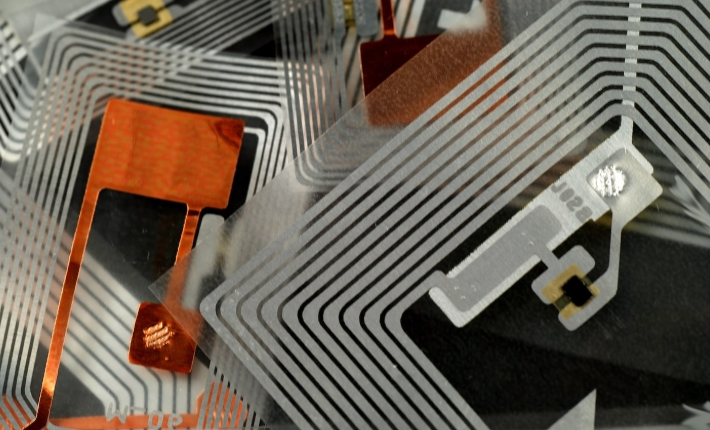

RFID electronic tag

The ID of an RFID tag contains information about a specific object. It can be attached to any physical surface, including raw materials, finished products, packaging, Flat noodles, pallets, etc. In industrial environments, passive tags are mainly used, which are tags without built-in batteries. This type of label is relatively cheap, but it requires the energy of a reader/writer to transmit data.

RFID antenna

The RFID antenna receives radio waves from the reader, provides energy for tag operation, and forwards radio signals from the tag to the reader.

RFID reader/writer

RFID readers can be fixed or handheld, and they use radio waves to read and write tags. The reader captures the ID information written in the tag repository and transfers it to the cloud along with the data of the reader's location and read time.

As inventory value may be an important component of a company's assets, inventory data is crucial for the accounting department to ensure the accuracy of the company's annual reports and tax returns.

RFID intelligent warehousing

Inventory management based on the Internet of Things has laid a solid foundation for the digitization of the manufacturing ecosystem and provides many benefits:

Automation of inventory tracking and reporting

With RFID and industrial IoT, inventory managers no longer need to spend time manually tracking and reporting. Each project will be tracked, and data related to it will be automatically recorded in a big data warehouse. Automated asset tracking and reporting can save approximately 18 hours of work time per month and reduce the likelihood of human error.

Continuous visibility into the quantity, location, and movement of inventory items

The IoT based inventory management solution provides manufacturers with real-time updates on the status, location, and movement of items, offering precise visibility into raw materials and components, as well as the production processes of work in progress and finished goods. This enables inventory managers to view when individual inventory items enter or leave a specific location.

Optimize inventory

The more warehouse managers understand inventory, the more likely they are to place the right items in the right location at the right time. With real-time data on inventory quantity and location, manufacturers can reduce inventory levels while meeting the needs of end of chain customers.

Identify bottlenecks in operations

With real-time data on the location and quantity of inventory items, manufacturers can reveal bottlenecks in the production process and identify machines with lower utilization rates. For example, if some inventory tends to pile up in front of the machines, the manufacturer will believe that the machines are not fully utilized and therefore require special attention.

Optimize delivery cycle

By providing warehouse managers with available inventory quantities and machine learning driven demand forecasting, industrial IoT based solutions can enable manufacturers to shorten delivery cycles.

With the application and popularization of RFID electronic tags, RFID intelligent warehouse management fundamentally solves the problem of further improving data reading speed and accuracy in various industries' warehouses. The adoption of RFID technology can achieve true wireless, long-distance, multi item, and dynamic identification functions, greatly improving warehouse management efficiency and achieving lean warehouse management.