Nowadays, more and more consumers choose customized solutions when shopping. For manufacturers, this means that many of the products they produce are unique. It can be foreseen that in future factories, a production line will install different models, which will have various types of information. Each device will constantly report its own status. It is crucial for manufacturing enterprises to accurately identify a product and collect diverse information during the production process.

By using RFID technology to improve the production process, it is possible to track products throughout the entire manufacturing process. This approach has also been well promoted in the manufacturing industry and has achieved significant results.

To achieve intelligent manufacturing, traditional barcodes have become outdated

Traditional barcode

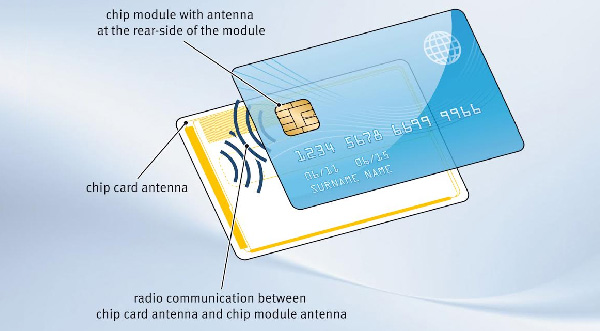

Currently, many traditional manufacturing companies use barcode technology to track parts. However, barcodes only store identification information, making the tracking solution too cumbersome and unreliable. RFID tags can contain all the historical records of a component and all the information about the product it is about to install. In addition, barcode reading must be done manually, and only one can be read at a time. RFID tags can be easily operated with just one RFID reader, and can even be read after the component is installed. Therefore, all information in RFID tags can be easily read anytime, anywhere in just a few seconds.

It can be said that RFID tag technology greatly improves product transparency, allowing workers to verify the status of all components that need to be installed on the product at any time during the installation process. Before the emergence of RFID tag technology, products could only be inspected during final verification, and workers visually inspected and checked using paper lists.

RFID tags not only improve product transparency, but also benefit the overall production of enterprises. For example, workshop project managers need more information from different sources than technicians. RFID tags can reduce blind spots in production scheduling, help workshop project managers understand the obstacles in the production process, and come up with reasonable solutions at the right time.

RFID tags help traditional manufacturing industry achieve intelligent "smart manufacturing"

Traditional manufacturing belongs to a typical large-scale production process with multiple trades, processes, and materials. Nowadays, with the development of personalized products (buyers can customize cars, treadmills, etc.), almost every product will have some personalized aspects. Therefore, it is necessary to apply RFID technology throughout the entire production process to achieve transparency.

Taking the application of RFID technology by car manufacturer Volvo as an example, before the use of RFID tags, Volvo cars used three independent systems to identify and track vehicles in manufacturing: using barcodes in the manufacturing workshop, using active RFID tags in the painting workshop, and using large barcodes in the assembly line. The combination of three systems not only results in high maintenance costs, but also lacks sufficient reliability. Even minor issues in the entire production process can affect the output of the entire factory.

Based on Volvo Cars' high requirements for quality and performance, the company uses powerful passive ultra-high frequency RFID tags that can be used in various harsh environments throughout the entire production process. In the manufacturing process, after leaving the welding workshop, the vehicle body will enter the painting line, and the harsh environment of the painting workshop determines that its requirements for labels are very high. The car body first needs to go through a corrosive electrolyte, and then goes through a series of layered painting and high-temperature drying ovens. The key is that after going through this series of harsh environments, the performance of this label has not decreased, and it still maintains its readability and reliability.